Properties

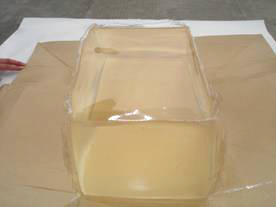

Mid Molecular Weight Polyisobutylene is a kind of transparent,,innoxious semi-solid. it is a colorless to light yellow, it is odorless or has a slight,characteristic odor, and tasteless. it stays stably with oxygen, ozone,acid,alkali,ultraviolet radiation and etc. Not dissolve in water, but gasoline and benzene.

Uses

1. Sealant: Polyisobutylene is the same with manufacture each kind of sealant to improve the products'flexility and penetrability.

2. Rubber: Polyisobutylene mixed with natural rubber and synthetic rubber ensures higher workability, addition of adhesion, and prevention of aging or cracking, improvement in resistance to water, electric insulation and resistance to ozone at normal and high temperatures.

3. Paraffin: Polyisobutylene mixed with paraffin can increase anti-draught ability and brittleness of paraffin , especially can improve the plasticity and anti-acid ability of the freezing food packaging.

4. Print Ink: Used as thickener and dispersant in polyethylene rotogravure print ink and add viscidity of print ink , prevent drying and splitting.

5. Lubricate Grease: Adding polyisobutylene to lubricate grease can improve the products' viscidity and ability of anti pressure.

6. Changing the character of macromolecule material,draught damp grease and etc.

Mid Molecular Weight Polyisobutylene is a kind of transparent,,innoxious semi-solid. it is a colorless to light yellow, it is odorless or has a slight,characteristic odor, and tasteless. it stays stably with oxygen, ozone,acid,alkali,ultraviolet radiation and etc. Not dissolve in water, but gasoline and benzene.

Uses

1. Sealant: Polyisobutylene is the same with manufacture each kind of sealant to improve the products'flexility and penetrability.

2. Rubber: Polyisobutylene mixed with natural rubber and synthetic rubber ensures higher workability, addition of adhesion, and prevention of aging or cracking, improvement in resistance to water, electric insulation and resistance to ozone at normal and high temperatures.

3. Paraffin: Polyisobutylene mixed with paraffin can increase anti-draught ability and brittleness of paraffin , especially can improve the plasticity and anti-acid ability of the freezing food packaging.

4. Print Ink: Used as thickener and dispersant in polyethylene rotogravure print ink and add viscidity of print ink , prevent drying and splitting.

5. Lubricate Grease: Adding polyisobutylene to lubricate grease can improve the products' viscidity and ability of anti pressure.

6. Changing the character of macromolecule material,draught damp grease and etc.

Features

- Sealant

- Polyisobutylene is the same with manufacture each kind of sealant to improve the products'flexility and penetrability.

- Rubber

- Polyisobutylene mixed with natural rubber and synthetic rubber ensures higher workability, addition of adhesion, and prevention of aging or cracking, improvement in resistance to water, electric insulation and resistance to ozone at normal and high temperatures.

- Paraffin

- Polyisobutylene mixed with paraffin can increase anti-draught ability and brittleness of paraffin , especially can improve the plasticity and anti-acid ability of the freezing food packaging.

- Print Ink

- Used as thickener and dispersant in polyethylene rotogravure print ink and add viscidity of print ink , prevent drying and splitting.

- Lubricate Grease

- Adding polyisobutylene to lubricate grease can improve the products' viscidity and ability of anti pressure.

Main Products

mid-molecular weight polyisobutylene