Pouch Making Machine For Three Side Seal Bag / Stand-Up Pouch / Zipper Pouch / Four Side Seal Bag

Product ID: FTSC-V

Send Inquiry

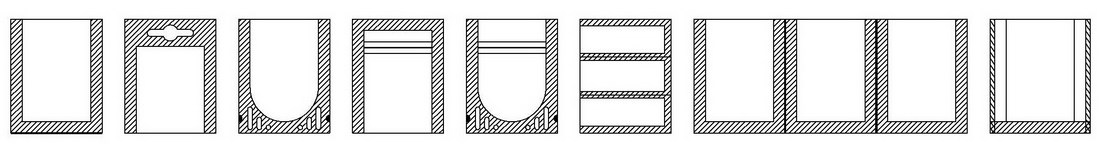

Suitable for sealable co-extrusion films, multi-layer films such as laminates of Polyester,BOPP and CPP... The FTSC-V Pouch Making Machine is ideal for the production of 3-side sealing bag, stand-up pouch, bottom gusseted stand-up pouch, zipper pouch, combined stand-up/zipper pouch, four side seal bag.

FTSC-V500, -V600 : Three Side Seal Pouch Making Machine

FTSC-V500-2, -V600-2 : Three Side Seal Bag/ Stand-Up Pouch Making Machine

FTSC-V500-3, -V600-3 : Three Side Seal Bag/ Stand-Up Pouch/ Zipper Pouch Making Machine

Features

- Main Mechanism

- Main drive servo motor: The operator can change the feeding and sealing time for each material independently. Sealing temperature adjustment unnecessary while machine speed up. This mechanism can help to reduce the lost of material greatly.

- Feeding servo motor*2: The pouch length is accurately controlled by servo motor includes middle pulling stand and rear pulling stand for upgrading production speed.

- Outer transmission mechanism: Compared with inner transmission mechanism, the structure of brand-new outer transmission mechanism is much simple and ease to maintenance

- The new FTSC-V pouch making machine can give about 30% more productivity than conventional bag making machines.

- Diverse range of bag production capabilities

- One machine can produce various pouches such as three side sealing bag, stand up pouch, bottom gusseted stand up pouch, zipper pouch, combined stand up and zipper pouch.

- 3-side sealing bag: 3 lanes production and the skip seal function can reach 9 times of feeding length. (max.1,200mm).

- Stand up pouch and zipper pouch: 2 lanes production.

- Bottom gusseted stand up pouch & Four side seal bag: Dual function unwind stand and a second add-on gusseting device are optional items that facilitate production of standup pouch with bottom gusset and four side seal bag. The adjustable gusseting depth, together with the gusset-nipping roller and photocell features, accurate gusset depth and precise sealing position can be achieved without film slip problem.

- One machine can produce various pouches such as three side sealing bag, stand up pouch, bottom gusseted stand up pouch, zipper pouch, combined stand up and zipper pouch.

- Web Handing And Tension Control

- The film takes many processes to convert to a pouch of demand size and shape. Most of the process are forming (folding and/or gusset forming), sealing in longitudinal and transverse directions, inserting other substrates such as zipper and gusset. Appropriate tension control is important to the composing process. The new FTSC-V Pouch Making Machine can set different tension values for each special tension zone to ensure the precise performance during pouch making machine running.

- Unwinding and forming zone: including unwind buffer roller unit and center partition buffer roller unit, the operator can use different buffer roller unit according to pouch shape. Each buffer roller unit is using the VR (Variable resistor) for auto speed varied and assures that the most stable web feeding even under high speed operation.

- Zipper / gusset inserting and zipper pouch sealing zone: The film enters into intermittent path from this zone. The zipper inserting tension is controlled by motor incorporated buffer roller unit in order to cope with the rush pulling that cause by intermittent path.

- Side sealing zone: The film is sealed longitudinally in this zone. And the tension is adjusted by the rear pulling stand which driven by servo motor and micro location offset via dancing roller control system.

- Bottom sealing zone: The film is sealed transversely in this zone. Therefore to avoid stretch in sealed area is the prime need. Through the middle pulling stand and micro location offset via dancing roller control system maintaining the minimum tension.

- The film takes many processes to convert to a pouch of demand size and shape. Most of the process are forming (folding and/or gusset forming), sealing in longitudinal and transverse directions, inserting other substrates such as zipper and gusset. Appropriate tension control is important to the composing process. The new FTSC-V Pouch Making Machine can set different tension values for each special tension zone to ensure the precise performance during pouch making machine running.

- Unwind Section

- Horizontal unwind stand and 3" air shaft incorporate with pneumatic loading device. Single operator is required to load the parent roll.

- Modify to two functions unwind stand which can produce one lane bottom gusset stand up pouch. (Patent No.M254422)

- Equipped with web guiding system (line/edge) which assured the accuracy of sealing and trimming position.

- The constant unwind tension is achieved by using tension auto controller (diameter calculating type) and magnetic powder brake.

- Equipped with material running out alarm device to prevent the effect of material broke.

- Both Side Printed Film Adjusting Device (Optional with secondly unwind stand )

- The adjustment is accurately controlled by servo motor incorporated with a contrast scanner. This device can eliminate the printing variations between upper and lower films automatically and reduce the defecting bags greatly.

- Pulling Stand And Micro Location Offset Tension Control System

- The movement of new dancing roller unit is controlled by two separate air pressure cylinders. According to the setting value, the system will detect and adjust the tension via change the feeding length of servo motor automatically. It is designed to provide the most stable tension during pouch making machine running.

- Zipper And Side Sealing Section

- The latest development of zipper pouch sealer and side sealer auto descending device which can prevent the material been overheated or broken when machine stop.

- HCI zipper guiding and cooling plate (Patent No.178721): This plate can steady the sealing position of zipper and the cooling circulation system can prevent the zipper pouch been overheated.

- Ultrasonic sealing device: it can weld the zipper rib in advance before entering the bottom sealer. The bottom sealed position will be flatted and perfected without leakage problem.

- Bottom Sealing Section

- Bottom sealer auto ascending device which can prevent the material been overheated or broken when machine stop. (Patent No.42360)

- Each bottom sealing unit can replace embossing plate with silicon plate; the operator can change the sealing arrangement for actual demand.

- Temperature Control System

- Microprocessor PID temperature controllers work with SSR (solid state relay). The system can process once communication control in 2 seconds and provide the most accurate and fastest heating performance.

- Temperature upper and lower limit alarm: the operator can alter the range of limit and auto stop function.

- Temperature auto tuning device: the sealing temperature varying with machine speed and the increasing rate can be changed.(Standard on FTSC-V Pouch Making Machine)

- Servo Cutter

- Newest cutter unit with easy adjustment and durable structure. The cutter unit can adjust the position from single side or whole unit moves front and rear.

- Cutter servo motor control system: The cutting speed is variable and the double cut function can eliminates burrs on in-line corner or notch puncher. This function improves the products quality.

- Man-Machine Interface Control System of FTSC Pouch Making Machine

- The automation man-machine system collocates with high-quality MES mechanical and electrical integrated controller. LCD colorful touch screen; Simple figure display for setting and easy operation.

- Three main drives speed control modes:

- Sealing time varies with cutting speed;

- Cutting speed varies with sealing time;

- Speed varies with heating extended time suitable for thicker film.

- Various bags modes setting: standard pouch/ multi-seal with single cut / skip-seal / double cut.

- Operation parameters could be saved in system such as cutting speed, pieces, length, temperatures etc...Parameters auto saving function when power failure happened.

- Intuitional malfunction detects system: monitor items include motors, inventors, control box communications, punchers, sensors, sealing temperatures etc... and the abnormal position will display on LCD directly. It is very convenient for operators to obviate the malfunction immediately.

- Safety Protection (Optional)

- Our main concern is not only complying with the safety regulations but the conveniences of operation. For zipper and side sealing section using the movable protecting cover, for bottom sealing section using the safety light curtain, for cutter section using the interlock switch, etc...

- Optional Accessories

- Two functions unwind stand.(For produce Bottom gusseted stand up pouch)

- Secondary gusseting device. (For produce Four side seal bag)

- Both side printed film adjusting device.

- Multiple punching devices.

- Product conveyer.

- Valve sealing device.

- Air chiller.

| Specifications | FTSC-V600-3 Pouch Making Machine |

|---|---|

| Material Width (mm) | 400 - 1,200 |

| Material Diameter (mm)(max.) | 600 |

| Bag Length (mm)(Max. 1,200mm skip-seal production) | 30 - 500 |

| Bag Width (mm)(Min. 75mm Multi-Lane Production) | 200 - 600 |

| Mechanical Speed (bags/min.) | 150 |

| Feeding Speed (m/min.) (max.) | 30 |

| Production Line | Three side sealing bag 1 - 3 Lanes |

| Stand up / zipper pouch 1 - 2 Lanes | |

| Bottom gusseted pouch 1 lane |

More Pouch Making Machine

Main Products

Slitting Machine, Slitter Rewinder, Rewinding machine, Laminating Machine, Bag Making Machine, Pouch Making Machine, Shrink Sleeve Making Machine, Sealing and Cutting Machine, Sheeting Machine, Embossing Machine, Paper Core Cutting Machine, Trim Winding Machine

Related Products

Contact Detail

-

Sales ContactAlan Ho

-

Address26, 7th Road, Taichung Industrial Park Taichung Taiwan (ZIP Code 40755)

-

Tel886-4-23590632

-

Fax886-4-23590710

-

E-mail

-

URL

HCI Converting Equipment Co., Ltd.

HCI Converting Equipment Co., Ltd.