2. Descriptions

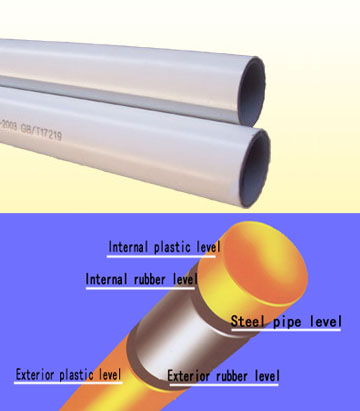

The main materials used are polyethylene and stainless steel. The inside and outside are polyethylene layers and stainless steel layer is in the middle. The technology ensures that the whole structure of the composite pipe is seamless. It uses a special technology to bond the two plastic layers and steel layer together in order to strengthen the whole pipe.

This product is revolutionary after the galvanization pipe was banned in China. It overcomes the shortcomings of pure steel pipe and pure plastic pipe and inherits the advantages of both. The product is very suitable for drink water, gas, chemical materials, mine, food industries and pharmacy industry, which are in need of long life, stable and environment-friendly pipes.

It can use electric-heat melting fittings to connect the pipes. However, it also can use metal fittings to connect.

3. Characteristics

a) The intensity, rigidity and anti-concussion outstrip that of pure plastic pipes;

b) Double surface antisepsis can endure higher temperature and various chemical materials;

c) Low diathermancy; no need to coat it to maintain the energy;

d) Isolates oxygen and other gases and liquids from penetrating inside, prevents contamination in the pipe system;

e) Smooth inside surface, not accumulate dirt, water pressure loss is less than steel pipes by 30%;

f) Use low cost electric-heat melting fittings to connect with various specifications available;

g) Light, easy to ship and install;

h) Reliable, workable for 70 years in normal circumstance;

i) Innocuous and environment friendly.

4. Applications

a) Chemical: Transportation of caustic gas, liquid, powder;

b) Oil field: Oil and gas sewage, crude oil;

c) Mining: Slurry, ventilator pipes etc.;

d) Textile, printing, dyeing and paper making: Discharge pipes;

e) Building: Water supply, gas, sewage;

f) Agriculture: All kinds of water supply pipes;

g) Shipbuilding: Various pipes on ships.

5. Technical specifications

Outer Diameter (mm) Thickness

(mm) Max. Working Pressure (MPa) Min. Damage Pressure (MPa)

Ф20 2.0 2.5 ≥7.5

Ф25 2.5 2.5 ≥7.5

Ф32 3.0 2.5 ≥7.5

Ф40 3.5 2.5 ≥7.5

Ф50 4.5 2.5 ≥7.5

Ф63 5.0 2.0 ≥6.0

Ф75 5.5 2.0 ≥6.0

Ф90 6.0 2.0 ≥6.0

Ф110 6.5 2.0 ≥6.0

details: please check our website: www.ragy.cn

Tel:+86-312-3860230/6670919

Fax: +86-312-3860230

Email:rongangs@126.com

MSN:liucan-001@hotmail.com

The main materials used are polyethylene and stainless steel. The inside and outside are polyethylene layers and stainless steel layer is in the middle. The technology ensures that the whole structure of the composite pipe is seamless. It uses a special technology to bond the two plastic layers and steel layer together in order to strengthen the whole pipe.

This product is revolutionary after the galvanization pipe was banned in China. It overcomes the shortcomings of pure steel pipe and pure plastic pipe and inherits the advantages of both. The product is very suitable for drink water, gas, chemical materials, mine, food industries and pharmacy industry, which are in need of long life, stable and environment-friendly pipes.

It can use electric-heat melting fittings to connect the pipes. However, it also can use metal fittings to connect.

3. Characteristics

a) The intensity, rigidity and anti-concussion outstrip that of pure plastic pipes;

b) Double surface antisepsis can endure higher temperature and various chemical materials;

c) Low diathermancy; no need to coat it to maintain the energy;

d) Isolates oxygen and other gases and liquids from penetrating inside, prevents contamination in the pipe system;

e) Smooth inside surface, not accumulate dirt, water pressure loss is less than steel pipes by 30%;

f) Use low cost electric-heat melting fittings to connect with various specifications available;

g) Light, easy to ship and install;

h) Reliable, workable for 70 years in normal circumstance;

i) Innocuous and environment friendly.

4. Applications

a) Chemical: Transportation of caustic gas, liquid, powder;

b) Oil field: Oil and gas sewage, crude oil;

c) Mining: Slurry, ventilator pipes etc.;

d) Textile, printing, dyeing and paper making: Discharge pipes;

e) Building: Water supply, gas, sewage;

f) Agriculture: All kinds of water supply pipes;

g) Shipbuilding: Various pipes on ships.

5. Technical specifications

Outer Diameter (mm) Thickness

(mm) Max. Working Pressure (MPa) Min. Damage Pressure (MPa)

Ф20 2.0 2.5 ≥7.5

Ф25 2.5 2.5 ≥7.5

Ф32 3.0 2.5 ≥7.5

Ф40 3.5 2.5 ≥7.5

Ф50 4.5 2.5 ≥7.5

Ф63 5.0 2.0 ≥6.0

Ф75 5.5 2.0 ≥6.0

Ф90 6.0 2.0 ≥6.0

Ф110 6.5 2.0 ≥6.0

details: please check our website: www.ragy.cn

Tel:+86-312-3860230/6670919

Fax: +86-312-3860230

Email:rongangs@126.com

MSN:liucan-001@hotmail.com

Specifications

dia20-dia200mm^$www.ragy.cn ^#dia20-dia200mm^$www.ragy.cn ^#dia20-dia200mm^$www.ragy.cn ^#dia20-dia200mm^$www.ragy.cn ^#dia20-dia200mm^$www.ragy.cn ^#Features

Main Products

HDPE pipe and PSP composite pipe