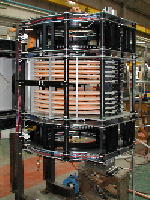

Merlin Induction Pipe and Tube Heating and Coating System

Product ID: Induction pipe heat

Send Inquiry

Radyne induction heating units are used for pre and post weld heat treatment of butt welded joints to insure joint integrity is achieved using manual or automated clam type interpass coils as well as heating prior to upsetting, annealing, FBE coating, in line anneal, and relaxation.

Integrated induction heating coils and powder coating heads enable both heating and coating of field joints to be completed simultaneously control through PLC and fiber optic connected pyrometry insure sharp heat cut off preventing debonding of coating on adjacent pipe areas.

Complete induction heating/coating system can be containerized with all ancillary equipment for use both on and off shore. Radyne builds induction systems for many applications with power levels available from 5kW to 6000kW.

Integrated induction heating coils and powder coating heads enable both heating and coating of field joints to be completed simultaneously control through PLC and fiber optic connected pyrometry insure sharp heat cut off preventing debonding of coating on adjacent pipe areas.

Complete induction heating/coating system can be containerized with all ancillary equipment for use both on and off shore. Radyne builds induction systems for many applications with power levels available from 5kW to 6000kW.

Features

- Powder coating unit

- Integrated coils and powder coating heads heat and coat of field joints simultaneously controlled through PLC

Main Products

Induction heat treating, induction brazing, induction billet forging