Related Keywords

- Compouding

- Conical Twin-Screw Extruder

- Mechanical Auxiliary Equipment

- PPR Pipe Extruder

- PVC Pipe Extruder

- Parallel Twin-Screw

- Plastic Extruder

- Plastic Extrusion

- Plastic Extrusion Line

- Plastic Pipe Extrusion Line

- Plastic Pipe Production Line

- Recycling

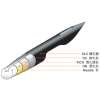

- Screw Barrel For Plastic Machines

- Single Screw Extruder

- Twin Screw Extruder

- Xps Foam