(1) The process route of bag-making

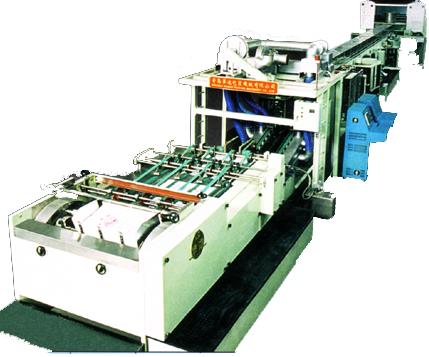

Coiling of plastic-weaved cloth (PP, PE) coiling up in bracket printing in obverse/front and reverse/back side with four up to six colors microperforating, cutting (equipping computer to treat ) bag tube turning rectifying and checking forward position orientation spreading glue stoving/drying opening bottom bag bottom adjusting pasting mouth of valve forming sticking attached bottom folding in reverse side to press producing bag and stacking up. The bag-making procedure is accomplished continually in one time, and the shape of the bag is valve mouth and square bottom

The whole product line assembles the control of machine, electricity and steam

product information:

This High Speed 4-Shuttle Leno Loom is used to weave tubular mesh (leno) bags for vegetable, onions, potatoes, fruits, etc. The machine is the highest speed China now for leno (mesh) bag project. Now, our had developed our new latest product--Double Use Leno Mesh Loom, which is designed to make normal Pp leno fabric, Pp leno fabric with labelling strip in the middle as well as normal Pp woven sack after convertion according to product season. Customers will be most welcome to visit our company for more details.

Coiling of plastic-weaved cloth (PP, PE) coiling up in bracket printing in obverse/front and reverse/back side with four up to six colors microperforating, cutting (equipping computer to treat ) bag tube turning rectifying and checking forward position orientation spreading glue stoving/drying opening bottom bag bottom adjusting pasting mouth of valve forming sticking attached bottom folding in reverse side to press producing bag and stacking up. The bag-making procedure is accomplished continually in one time, and the shape of the bag is valve mouth and square bottom

The whole product line assembles the control of machine, electricity and steam

product information:

This High Speed 4-Shuttle Leno Loom is used to weave tubular mesh (leno) bags for vegetable, onions, potatoes, fruits, etc. The machine is the highest speed China now for leno (mesh) bag project. Now, our had developed our new latest product--Double Use Leno Mesh Loom, which is designed to make normal Pp leno fabric, Pp leno fabric with labelling strip in the middle as well as normal Pp woven sack after convertion according to product season. Customers will be most welcome to visit our company for more details.

Main Products

CIRCULAR LOOM, PP TAPE EXTRUDER, LENO LOOM FOR PP/HDPE WOVEN SACK/BAG