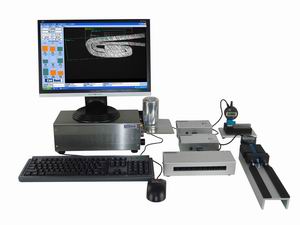

Full Automatic Seam Monitor (V3)

Canneed Seam SightTM Full Automatic Seam Monitor (V3) has adopted the advanced optical system and Golden LensTM video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam SightTM system is equipped with the new seam measuring software Seam SightTM.

Seam SightTM professional seam measuring software will do the line positioning automatically and the measurement to be finished within 1 second! The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

The magnifier option enable users to magnify the testing image for a more accurate line positioning, so that the measurement results are more accurate and reliable.

Seam SightTM Full Automatic Seam Monitor (V3), consisting of:

1)Seam SightTM Video Seam monitor

2)Seam SightTM 2.0 professional Seam measurement software

3)Calibration piece 2mm

Option:

4)CSS series Seam Saw

5)CanNeed SPC data collection system, included:

STG-200-d Seam Thickness Gauge (digital)

CSG-d Countersink Gauge (digital)

ADI-100 Adapter of Digital Indicator

TRC-200 Transporter of Computer

CMDI Mitutoyo cable Seam SightTM

Full Automatic Seam Measurement System

Use the CanNeed SPC data collection system,

The actual seam thickness, actual countersink, etc., can be transferred to the computer automatically

Features:

Full automatic line positioning (Auto measure), measurement finished within 1 second!

Equipped with Golden LensTM video capture device which interference-free of external light source and ensured the high image definition

Software adopted data base management system, measurement results and images saved in the data base and users can review or re-measure the saved projects at any time

12 Measuring Items: Seam Length, Body Hook Length, End Hook Length, Overlap, Seam gap, Overlap rate, Body Hook lapping rate, End Hook lapping rate, On-screen Seam Thickness; Actual Seam Thickness; Actual countersink; Tightness

SPC compatible, use a data adapter to collect the data from Mitutoyo Digital Indicator (Actual Seam Thickness; Actual countersink)

Data can be exported as an Excel file

Report format can be customized, flexible for different report styles of different companies

Predefine various qualification standards, auto judge and warn whether the results are qualified in every measure

Measurement results and label lines mark directly on the image, results will also display in corresponding field on the screen

Graph chart statistic function, automatically analyze and compare the measurement results

Magnifier option enable users to magnify the testing image for a more accurate line positioning

Measured values are displayed in on-screen and alarm if values are not within specs

Seam image can be printed, stored

Provided with calibration piece, calibrate at any time

Use the monochromatic source, make it much more durable

Optional for large measuring support, able to measure big cans or paid

Able to measure triple seam

(Auto measure function is not available for triple seam)

Measurement results and images saved in the data base management system. Convenience for overview and recheck Various statistics charts analyze the products quality automatically.

Technical data (changes reserved):

Power supply : 115 V/230V

Serial interface : RS 232 C

Resolution : 0.001mm

Accuracy : 0.005 mm

Magnification factor : 60 X

Line positioning magnification factor : 180 X

Languages : English / Chinese

Cans dia. : 52-200 mm, custom made up to 300

Dimensions : 400 x 200 x 150 mm(W x D x H)

Net Weight : 7.5 kg

Computer Configuration Requirement:

CPU series :Celeron dual core or above

CPU Model :Intel® Celeron® Processor E3200 (1M Cache, 2.40 GHz, 800 MHz FSB) or above

Mainboard / RAM :1024MB / DDRII 800MHz or above

Hard Disc :SATA2 (7200rpm) / 80GB or above

CD Driver :16X / DVD-ROM or above

Graphic card :64M / independent graphics card or above

Sound card :integrated

Network :100Mbps Ethernet NIC

Other :4 USB2.0 port or more

Operating System :Windows XP or WIN7

Seam SightTM professional seam measuring software will do the line positioning automatically and the measurement to be finished within 1 second! The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

The magnifier option enable users to magnify the testing image for a more accurate line positioning, so that the measurement results are more accurate and reliable.

Seam SightTM Full Automatic Seam Monitor (V3), consisting of:

1)Seam SightTM Video Seam monitor

2)Seam SightTM 2.0 professional Seam measurement software

3)Calibration piece 2mm

Option:

4)CSS series Seam Saw

5)CanNeed SPC data collection system, included:

STG-200-d Seam Thickness Gauge (digital)

CSG-d Countersink Gauge (digital)

ADI-100 Adapter of Digital Indicator

TRC-200 Transporter of Computer

CMDI Mitutoyo cable Seam SightTM

Full Automatic Seam Measurement System

Use the CanNeed SPC data collection system,

The actual seam thickness, actual countersink, etc., can be transferred to the computer automatically

Features:

Full automatic line positioning (Auto measure), measurement finished within 1 second!

Equipped with Golden LensTM video capture device which interference-free of external light source and ensured the high image definition

Software adopted data base management system, measurement results and images saved in the data base and users can review or re-measure the saved projects at any time

12 Measuring Items: Seam Length, Body Hook Length, End Hook Length, Overlap, Seam gap, Overlap rate, Body Hook lapping rate, End Hook lapping rate, On-screen Seam Thickness; Actual Seam Thickness; Actual countersink; Tightness

SPC compatible, use a data adapter to collect the data from Mitutoyo Digital Indicator (Actual Seam Thickness; Actual countersink)

Data can be exported as an Excel file

Report format can be customized, flexible for different report styles of different companies

Predefine various qualification standards, auto judge and warn whether the results are qualified in every measure

Measurement results and label lines mark directly on the image, results will also display in corresponding field on the screen

Graph chart statistic function, automatically analyze and compare the measurement results

Magnifier option enable users to magnify the testing image for a more accurate line positioning

Measured values are displayed in on-screen and alarm if values are not within specs

Seam image can be printed, stored

Provided with calibration piece, calibrate at any time

Use the monochromatic source, make it much more durable

Optional for large measuring support, able to measure big cans or paid

Able to measure triple seam

(Auto measure function is not available for triple seam)

Measurement results and images saved in the data base management system. Convenience for overview and recheck Various statistics charts analyze the products quality automatically.

Technical data (changes reserved):

Power supply : 115 V/230V

Serial interface : RS 232 C

Resolution : 0.001mm

Accuracy : 0.005 mm

Magnification factor : 60 X

Line positioning magnification factor : 180 X

Languages : English / Chinese

Cans dia. : 52-200 mm, custom made up to 300

Dimensions : 400 x 200 x 150 mm(W x D x H)

Net Weight : 7.5 kg

Computer Configuration Requirement:

CPU series :Celeron dual core or above

CPU Model :Intel® Celeron® Processor E3200 (1M Cache, 2.40 GHz, 800 MHz FSB) or above

Mainboard / RAM :1024MB / DDRII 800MHz or above

Hard Disc :SATA2 (7200rpm) / 80GB or above

CD Driver :16X / DVD-ROM or above

Graphic card :64M / independent graphics card or above

Sound card :integrated

Network :100Mbps Ethernet NIC

Other :4 USB2.0 port or more

Operating System :Windows XP or WIN7

Main Products

the Quality Control Instruments and total solution for Can-making