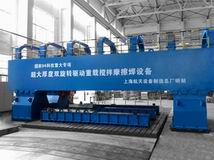

Dual Rotation Heavy-load FSW Equipment for Extra-thickness Plates

Product ID: HT-JM80×63/3

Send Inquiry

Technical Specifications:

Structural Type:Double Gantry Structure

Max Thickness:80mm

X(Traverse):0-6300mm

Y(Cross):0-6000mm

Z(Plunge):0-500mm

Machine size:13500mm×9000mm×4500mm

Table Size:6000×5000mm

X-axis speed:5~1500mm/min

Y-axis speed:5~1500mm/min

Z-axis speed:5~350mm/min

A axis adjustment:0~5°Manual

Control System:5-axis CNC System of Parallel Mechanism

Equipment Features:

1、The equipment is used for linear and curved welding of aluminum alloy plates with welding length ≤6300mm,Its single-sided welding thickness ranges from 2 to 80mm, and double-sided welding thickness ranges from 2 to 150mm;

2、5-axis CNC Technology of Parallel Mechanism is used in FSW equipment for the first time in China, which could result in continuous curved weld with high conformity;

3、Thermal field control is used to guarantee consistency of weld structure and conformity of mechanical property;

4、Adaptive control of constant pressure is used to guarantee weld quality;

5、M

Structural Type:Double Gantry Structure

Max Thickness:80mm

X(Traverse):0-6300mm

Y(Cross):0-6000mm

Z(Plunge):0-500mm

Machine size:13500mm×9000mm×4500mm

Table Size:6000×5000mm

X-axis speed:5~1500mm/min

Y-axis speed:5~1500mm/min

Z-axis speed:5~350mm/min

A axis adjustment:0~5°Manual

Control System:5-axis CNC System of Parallel Mechanism

Equipment Features:

1、The equipment is used for linear and curved welding of aluminum alloy plates with welding length ≤6300mm,Its single-sided welding thickness ranges from 2 to 80mm, and double-sided welding thickness ranges from 2 to 150mm;

2、5-axis CNC Technology of Parallel Mechanism is used in FSW equipment for the first time in China, which could result in continuous curved weld with high conformity;

3、Thermal field control is used to guarantee consistency of weld structure and conformity of mechanical property;

4、Adaptive control of constant pressure is used to guarantee weld quality;

5、M

Certificate

- GJB9001B-2009

Main Products

Friction Stir welding, friction stir spot welding machine