Research and Development

R & D

Location: TaiwanInnovation/Improvement Details

With the improvement of society and the raise of life level, the quality of common products is better and better. However, what we are surprised is that among nearly one hundred sewing factories that we have visited, more than half of them are not careful to the selection of sewing needle. Only about 40% of those factories have initial knowledge select the sewing needles suitable to make up goods.

Generally, the greatest problem is to select wrong needlepoint. For example, it shall select small eyelet stitch (SES) for jersey cloth, but some factories select sharp point ( R) instead thus cause yarn breakage; it shall select common needle for synthetic leather, but the selection of cutter needle will cause breakage of leather.

Such a mistake will lead to the wrong way for improving quality of product and good product rate in such an era full of intensive competition.

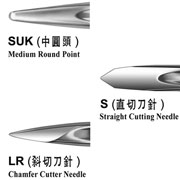

Strictly speaking, there are many types of needlepoint. We give simple classification and description (Figure 1) upon the common needlepoint currently used, so as to provide reference to the persons engaged in this industry.

The different needlepoint is used for different sewing materials.

We can simply classify the sewing materials as the following three types:

1. Plain stitch cloth (woven cloth)

2. Jersey cloth

3. Plane

organization material, for example leather, canvas, nylon cloth, etc.

For plain stitch cloth, the sharp needle( R) is selectable for making up. The reason is that this cloth will not be extended due to the breakage of a strand of yarn in cloth. The type SES can also be used for this case, and the principle is that the small round ball will smooth to the left or right of fiber while contacting fiber. It will not destroy the yarn and therefore will prolong the service life of cloth.

But for this reason, the stitch is not straight after making up, and for very thin plain stitch cloth, the sewing stitch will be easily wrinkled due to increase of resistance. If there is elastic rubber in the plain stitch cloth, the selection of needlepoint shall be mainly from type SES and SUK.

Jersey cloth is different with plain stitch cloth in the structure of knitting. If a strand of yarn is broken in the course of sewing, this hole will be enlarged gradually, so it shall select SES or SUK whether or not the cloth contains elastic material. Concerning the size of round head, its selection is based on the count of jersey

cloth and fineness of yarn.

We also have a simple method for reference, that is the size of ball point of needlepoint. When it is about 0.8~1.3 times of diameter of yarn, this is suitable fitting between needlepoint and single wrap. The size of small round head is

commonly one tenth of diameter of needle body, and medium round head as one fifth.

All of these are known and determined, so we can easily get to know how to select the size of round head with the above-mentioned methods.

Contact Detail

-

CEOMr. Shou-Te Chen

-

Sales ContactAndrew Kuang

-

AddressNo. 49, Lane 11, Hua-Cheng Rd., Hsin Chuang District New Taipei City, 24252 Taiwan, R.O.C.

-

Tel886-2-22775877

-

Fax886-2-22775055

-

E-mail

-

URL